Our Products

Spiral Bevel Gear

A spiral bevel gear is a type of gear used in mechanical systems to transmit power and motion between intersecting shafts at right angles. It is a specialized form of bevel gear, which is a gear with teeth that are cut at an angle to the face of the gear.

The spiral bevel gear has curved teeth that are cut in a spiral pattern around the gear’s circumference. This spiral shape allows the gear to transmit power smoothly and quietly, with reduced vibration and noise compared to straight-cut bevel gears. The spiral teeth also provide a gradual engagement, resulting in improved load distribution and higher torque capacity.

About

What Are Bevel Gears Used For

Bevel gears are widely used in various industries and applications where the transmission of power and motion between intersecting shafts at an angle is required. Their unique tooth shape and design make them suitable for specific tasks. Bevel gears are commonly found in automotive differentials, where they allow power to be transmitted from the engine to the wheels at right angles. They are also utilized in industrial machinery, such as machine tools, where they enable precise and synchronized movements. In the aerospace industry, bevel gears are employed in helicopter transmissions to transfer power from the engine to the rotor blades. Additionally, bevel gears find applications in marine propulsion systems, power transmission systems, mining and construction equipment, robotics, and automation. Their versatility, strength, and ability to handle heavy loads make bevel gears indispensable in a wide range of mechanical systems where angular power transmission is required.

Spiral Bevel Gear Applications

Power Transmission Systems

Spiral bevel gears are employed in power transmission systems where right-angle gearboxes are required. They are used in applications like conveyors, pumps, compressors, and generators, ensuring reliable and efficient power transfer.

Spiral bevel gears find applications in various industries and mechanical systems where efficient power transmission and high precision are required. Some common applications of spiral bevel gears include:

Industrial Machinery

Spiral bevel gears are used in various industrial machinery, such as machine tools, printing presses, and packaging equipment. They facilitate the transmission of power between intersecting shafts at right angles and help maintain accurate and synchronized movements.

Automotive Industry

Spiral bevel gears are extensively used in automotive differentials to transfer power from the drive shaft to the wheels. They help distribute torque between the wheels and enable smooth and controlled turning of the vehicle.

Aerospace Industry

Spiral bevel gears are employed in helicopter transmissions to transmit power from the engine to the rotor blades. They play a crucial role in maintaining stability and control during flight.

Marine Applications

Spiral bevel gears are utilized in marine propulsion systems, such as boat and ship engines, to transfer power from the engine to the propeller shaft. They ensure smooth power transmission and enable efficient propulsion.

Miter Gear VS Bevel Gear

Miter gears and bevel gears are both types of gears used for transmitting power and motion between intersecting shafts at right angles. While they share some similarities, there are distinct differences between the two.

Miter gears, also known as mitre gears, are a specific type of bevel gear. They have the same characteristics as bevel gears in terms of tooth shape and operation. However, miter gears are specifically designed for applications where the intersecting shafts are at a 90-degree angle and have the same number of teeth. This means that miter gears are interchangeable, allowing for easy reversal of direction without changing the gear ratio. They are commonly used in applications such as hand drills, woodworking tools, and some types of machinery.

On the other hand, bevel gears refer to a broader category of gears that include not only miter gears but also spiral bevel gears, straight bevel gears, hypoid gears, and zerol gears. Bevel gears have teeth that are cut at an angle to the gear’s face and are used in applications where the shafts intersect at any angle other than 90 degrees. They are employed in various industries such as automotive, aerospace, industrial machinery, and marine applications.

In summary, miter gears are a specific type of bevel gear used for 90-degree intersections with equal tooth numbers, while bevel gears encompass a wider range of gear types used for intersecting shafts at various angles. The choice between miter gears and other types of bevel gears depends on the specific application requirements, such as angle of intersection, gear ratio, and load capacity.

Types of Bevel Gears

There are several types of bevel gears, each with its own unique design and application. The main types of bevel gears include:

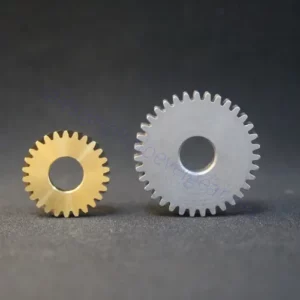

Straight Bevel Gear

Straight bevel gears have teeth that are straight and parallel to the axis of the gear. They are the simplest and most common type of bevel gear. Straight bevel gears are used when the intersecting shafts are at 90 degrees to each other.

Spiral Bevel Gear

Spiral bevel gears have curved teeth that form a spiral pattern around the gear’s circumference. This design allows for smoother and quieter operation compared to straight bevel gears. Spiral bevel gears are ideal for applications that require high precision, load-carrying capacity, and low noise, such as automotive differentials and helicopter transmissions.

Hypoid Gear

Hypoid gears are similar to spiral bevel gears but have an offset axis. The pinion gear is mounted at a 90-degree angle to the gear axis, resulting in a hybrid shape. Hypoid gears are commonly used in automotive rear axles and power tools, where the offset design allows for compact and efficient power transmission.

Zerol Bevel Gear

Zerol bevel gears are similar to spiral bevel gears but have curved teeth that are angled in a specific manner to reduce the axial thrust generated during operation. This makes them ideal for applications where minimizing axial loads is important, such as high-speed gearboxes.

Crown Gear

Crown gears, also known as contrate gears, are bevel gears with teeth that are perpendicular to the gear axis. They are typically used in applications where rotation direction needs to be changed by 90 degrees, such as in clocks and certain types of mechanical systems.

Skew Bevel Gear

Skew bevel gears are a specialized type of bevel gear with teeth that are angled and twisted. They are used when the intersecting shafts are not at 90 degrees to each other but have a skew angle. Skew bevel gears are commonly found in applications involving non-parallel and intersecting shafts, such as printing presses and packaging machinery.

Blog

Latest From Our blog

China Good quality Made in China Rotary Table Zp37.5 Spiral Bevel Gear (OD1540mm) with Best Sales

China Hot selling K Series Spiral Bevel Gear Motor Without IEC motor manufacturer

China Best Sales Wholesale High Precision Spiral Bevel Gear for 6-100 Angle Grinder Power Tool Spare Parts hypoid bevel gear

Spiral Bevel Gear for Sale

As a spiral bevel gear manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

-

Cnc High Quality Professional Oem Spiral Bevel Gear

-

High-Grade New Design Custom Alloy Steel Bevel Gear

-

Industrial and Agricultural Machinery Parts Large Diameter Custom Spiral Bevel Gears

-

OEM Milled Spiral Bevel Gears for Concrete Machinery

-

Professional Customized High-Quality Spiral Bevel Gear

-

Rack and Pinion and Spiral Bevel Gear Pinion

Why Choose Spiral Bevel Gears?

There are several compelling reasons to choose spiral bevel gears for various applications. Firstly, their unique tooth shape and spiral design provide smooth and gradual engagement, resulting in reduced noise, vibration, and impact loads. This makes them ideal for applications where quiet operation is essential, such as automotive differentials or precision machinery.

Secondly, spiral bevel gears offer high load-carrying capacity due to their curved teeth and optimized tooth contact pattern. The gradual engagement ensures even distribution of the load across the teeth, minimizing wear and increasing the gears’ durability. This makes them well-suited for heavy-duty applications that require reliable and long-lasting performance.

Thirdly, spiral bevel gears provide excellent precision and accuracy. The spiral tooth shape allows for precise motion control and synchronization between intersecting shafts at right angles. This makes them suitable for applications such as robotics, machine tools, and automated systems where precise movement and positioning are critical.

Moreover, spiral bevel gears are designed to handle a wide range of operating conditions, including high speeds, heavy loads, and varying torque requirements. Their robust construction and efficient power transmission capabilities make them versatile in industries such as automotive, aerospace, marine, and industrial machinery.

Choosing the Correct Bevel Gear Manufacturer

In order to ensure you receive the best possible outcome when you purchase bevel gears from a gear manufacturer, it’s crucial to assess the different businesses by using our list of manufacturers of bevel gear. Each manufacturer of bevel gear includes a page on their profile for business with a list of their experience and capabilities, as well as a contact form that allows you to contact the manufacturer for more details or an estimate. Go through each company’s site using our exclusive website previewer tool to quickly understand the areas of expertise each company is specialized in. Use our easy Request for Quotation form to direct reach out to multiple companies using this same form.